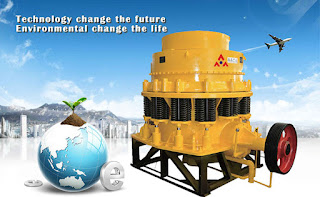

Cone crusher plays an important role in hard stone crushing. XHP new hydraulic cone crusher is developed on the basis of spring cone crusher, professional in crushing hard stone, ores.

XHP new hydraulic cone crusher is more suitable for iron ore, nonferrous metal ore, granite, limestone, quartzite, pebbles and other rock and ore crushing, by the domestic customer favorite.

Compared with spring cone crusher, XHP new hydraulic cone crusher has a higher production efficiency, greater production capacity, better grain type, a higher degree of automation, maintenance more convenient.

Jiaozuo Xin Heavy Industrial Machinery Co., Ltd. is China's leading manufacturer of crushing and screening equipment, specializing in the production of cone crusher, jaw crusher, impact crusher, vibrating feeder, vibrating screen, sand making machine and other equipments., HP hydraulic cone crusher, PSG Symons cone crusher, PE jaw crusher, VSI crusher series are exported to overseas.

keywords:hydraulic cone crusher,hard material crusher,iorn crsuher,ore crusher,

http://www.zxelsp.com/news/69.html